Nextteq® provides quality dosimeter tubes for TWA monitoring -

Over 40 applications available - Sampling Made Simple.

Dosimeter Tubes-

Dosimeter tubes are a very simple and economical way to obtain a TWA reading. A dosimeter tube is a direct read glass tube that uses the principle of the natural diffusion of gas. A passive diffusion process provides users with flexible sampling periods ranging from a half-hour to 48 hours! This allows very short exposures for capturing peak events and long exposures for accurate low concentration air quality measurements.

Dosimeter tubes can be worn on an individual for worker safety.

The passive dosimeter can then be positioned in the worker's breathing zone where it can be attached with a Nextteq dosimeter tube holder and the amount of individual exposure can be measured. The indication can be read and recorded at any time: during the work shift, at the end of the work shift, at the end of an overtime shift, or for some tubes as late as 48 hours after activation.

Dosimeter tubes can also be used as an analytical tool.

Stationary use is also possible for TWA measurements within a fixed environment over longer periods, such as the course of a whole day. For example, in the wine industry, SO₂ is used around produce as a fumigant and mold preventative. Dosimeter tubes are placed into a smaller room or chamber while the gas is being applied. Then, after mitigation, a reading can be taken from a dosimeter tube to ensure that adequate levels were achieved. These tubes can be placed on a door or window where they can safely be read. Before any reentry, a short-term detection tube (or direct reading single gas monitor like the NXS-SO₂) can be used to ensure that the residual levels are safe for employee entrance either with or without a respirator.

DID YOU KNOW?

-

Dosimeter Tubes are Simple, Pre-Calibrated, Direct-Read TWA Monitoring Method of Airborne Contaminants

Nextteq® distributes Nextteq® brand-labeled dosimeter tubes as well as dosimeter tubes manufactured by Gastec®. These dosimeter tubes provide users with a simple way to perform TWA monitoring of airborne contaminants. These are length-of-stain tubes with an indication proportionate to the amount of the gas contaminant present, ending with a distinct line of demarcation. The line of demarcation is read against a pre-calibrated measurement scale which is as easy to read as a thermometer and provides exposure levels in parts per million (PPM) hours.

-

Always Ready to Use with Many Applications and Ranges to Choose From

Dosimeter tubes are always ready to use and operate by direct diffusion exposure, so no cumbersome sampling pumps are needed. There is no user calibration, extra equipment, laboratory analysis, lengthy calculations or extensive training required. Dosimeter tubes reduce administrative and maintenance time and the possibility of user error. And, with a large variety of applications and sampling ranges, you have greater flexibility to cover all your detection needs.

-

Versatile and Economical Sampling System

Dosimeter tubes provide an inexpensive way to assess average gas concentrations. There is no need to make multiple worksite visits to change the sampling media. Dosimeter tubes decrease your costs and risk of error by allowing you to accurately make repeated TWA measurements with the same dosimeter tube.

-

Accurate and Reliable Personnel and Area Monitoring

Dosimeter tubes are labeled with the application name and part number to provide easy selection and traceability. For guaranteed accuracy and reliability, calibration scales for dosimeter tubes are printed on each tube for each individual production lot. You avoid problems associated with accuracy or quality that are found with competitive systems that use a common calibration scale for different production lots.

With no ambiguous color comparison charts or wheels, users don't have to worry about errors resulting from inaccurate color matching. New tubes can be issued to each employee at the start of each shift with readings taken at the end of the shift to record an individual’s daily exposure, contributing to a comprehensive worker’s exposure history. Dosimeter tubes are highly sensitive and selective to the targeted chemicals, as opposed to other non-specific testing methods. Dosimeter tubes can monitor TWA gas concentrations in a specific location or they can be worn on lapel clips to monitor an employee’s exposure to potentially harmful gases over the course of the workday.

To obtain a TWA reading, simply note the end of the color change and record your reading. Then, simply divide by the number of hours for the TWA (PPM hours/hours worked).

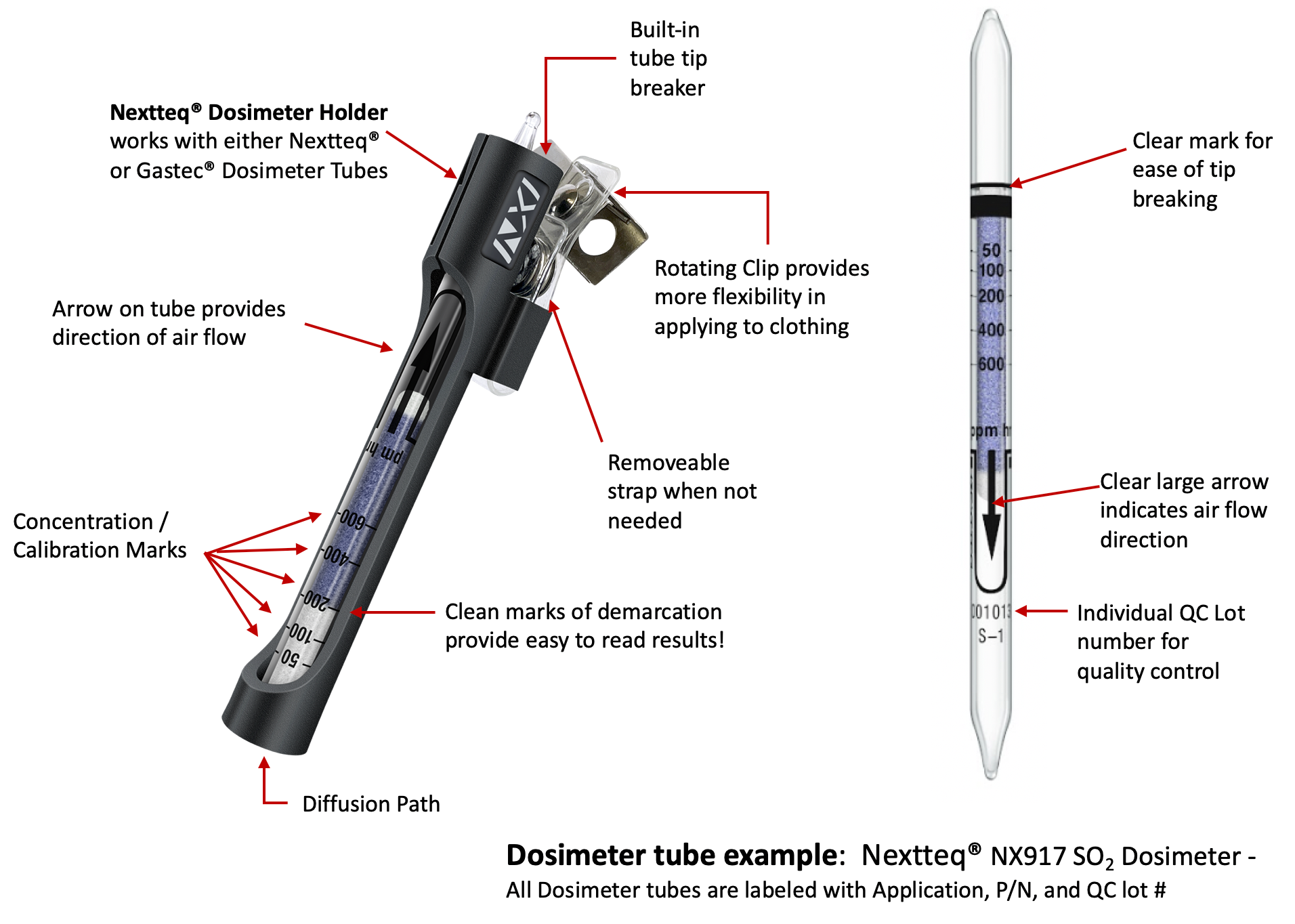

NEW! Nextteq® Tube Holder

Comfortable, Easy-to-Wear and Safe

Dosimeter tubes are rugged, precision instruments about the size of a fountain pen, which snap securely into the lightweight tube holder. The Nextteq® tube holder is clipped easily to workers’ clothing for true breathing zone measurements without the need for sampling pumps. The convenient and reusable tube holder allows for safe tube end removal and secure sampling. Manufactured with a corrosion-resistant, high-impact plastic, this durable and rugged tube holder is designed to withstand the rigors of harsh workplace environments and is available in packs of 3.

Ordering Information

Dosimeter Tube Holders - 3/bag - P/N 90460-3

| Substance to be measured | Tube Number | Brand Nextteq (NXI) Gastec (G) | Tube Name | Measuring range | Scale range |

|---|---|---|---|---|---|

| Acetaldehyde | 151D | G | Acetone | 4-1200 | |

| 152D | G | Methyl ethyl ketone | 1.2-360 | ||

| 91D | G | Formaldehyde | 0.1-20 | 1-20ppm・hr | |

| Acetic acid | 81D | G | Acetic acid | 0.5-100 | 5-100ppm・hr |

| Acetic anhydride | 81D | G | Acetic acid | 0.3-60 | |

| Acetone | 151D | G | Acetone | 5-1500 | 50-1500ppm・hr |

| 152D | G | Methyl ethyl ketone | 1.4-420 | ||

| Ammonia | 3D | G | Ammonia | 2.5-1000 | 25-500ppm・hr |

| 3DL | G | Ammonia | 0.1-10 | 1-10ppm・hr | |

| Benzene | 122DL | G | Toluene | 2.4-600 | |

| 1,3-Butadiene | 174D | G | 1,3-Butadiene | 1.3-200 | 10-200ppm・hr |

| Carbon dioxide | 2D | G | Carbon dioxide | 0.02-12% | 0.2-6.0%・hr |

| Carbon monoxide | 1D | G | Carbon monoxide | 1.04-2000 | 50-1000ppm・hr |

| 1DL | G | Carbon monoxide | 0.4-400 | 10-200ppm・hr | |

| Chlorine | 132D | G | Trichloroethylene | 2.4-240 | |

| 8D | G | Chlorine | 0.08-100 | 2-50ppm・hr | |

| Cumene | 122DL | G | Toluene | 3.4-850 | |

| trans-1,2-Dichloroethylene | 174D | G | 1,3-Butadiene | 3.8-600 | |

| 1,2-Dichloroethylene | 132D | G | Trichloroethylene | 6-600 | |

| Dimethylamine | 3D | G | Ammonia | 1.9-750 | |

| N,N-Dimethylethylamine | 3D | G | Ammonia | 4-1600 | |

| Ethanol | 112D | G | Ethanol | 100-25000 | 1000-25000ppm・hr |

| Ethyl benzene | 122DL | G | Toluene | 2.8-700 | |

| Ethylene | 174D | G | 1,3-Butadiene | 1.5-240 | |

| Formaldehyde | 91D | G | Formaldehyde | 0.1-20 | 1-20ppm・hr |

| Formic acid | 81D | G | Acetic acid | 0.55-110 | |

| Furfural | 91D | G | Formaldehyde | 0.3-60 | |

| Hydrazine | 3D | G | Ammonia | 1.6-650 | |

| Hydrogen chloride | 132D | G | Trichloroethylene | 1.8-180 | |

| 14D | G | Hydrogen chloride | 1-100 | 10-100ppm・hr | |

| 17D | G | Hydrogen fluoride | 0.4-40 | ||

| Hydrogen cyanide | 12D | G | Hydrogen cyanide | 1-200 | 10-200ppm・hr |

| Hydrogen fluoride | 14D | G | Hydrogen chloride | 2.5-250 | |

| 17D | G | Hydrogen fluoride | 1-100 | 10-100ppm・hr | |

| Hydrogen peroxide | 32D | G | Hydrogen peroxide | 0.5-40 | 5-40ppm・hr |

| Hydrogen sulfide | 4D | G | Hydrogen sulfide | 0.2-200 | 10-200ppm・hr |

| Isoprene | 174D | G | 1,3-Butadiene | 2.5-400 | |

| Methyl ethyl ketone | 151D | G | Acetone | 6.5-1950 | |

| 152D | G | Methyl ethyl ketone | 2-600 | 20-600ppm・hr | |

| 91D | G | Formaldehyde | 0.125-25 | ||

| Methyl isobutyl ketone | 151D | G | Acetone | 11.5-3450 | |

| 152D | G | Methyl ethyl ketone | 4-1200 | ||

| Methylamine | 3DL | G | Ammonia | 0.19-19 | |

| Nitric acid | 14D | G | Hydrogen chloride | 0.8-80 | |

| 17D | G | Hydrogen fluoride | 0.32-32 | ||

| Nitrogen dioxide | 9D | G | Nitrogen dioxide | 0.1-30 | 1-30ppm・hr |

| 9DL | G | Nitrogen dioxide | 0.01-3.0 | (0.1)-3.0ppm・hr | |

| Styrene | 122DL | G | Toluene | 26-6500 | |

| Sulfur dioxide | NX917 | (NXI) | Sulfur dioxide | 10-600 | 50-600ppm・hr |

| 5DH | G | Sulfur dioxide | 10-600 | 50-600ppm・hr | |

| 5D | G | Sulfur dioxide | 0.2-100 | 2-100ppm・hr | |

| Tetrachloroethylene | 133D | G | Tetrachloroethylene | 3-150 | 25-150ppm・hr |

| 132D | G | Trichloroethylene | 1.5-150 | ||

| Toluene | 122DL | G | Toluene | 2-500 | 20-500ppm・hr |

| Trichloroethylene | 132D | G | Trichloroethylene | 3-300 | 25-300ppm・hr |

| Triethylamine | 3D | G | Ammonia | 5.3-2100 | |

| Trimethylamine | 3DL | G | Ammonia | 0.23-23 | |

| Vinyl chloride | 174D | G | 1,3-Butadiene | 1.5-240 | |

| Xylene | 122DL | G | Toluene | 3.4-850 |

Contact UsTo reach the Nextteq #1 Customer Service Team call 813-249-5888

or toll free at 877-312-2333

©2023 Nextteq International LLC. All rights reserved. Nextteq, Nextteq logo, NXI, NXI logo, VeriFit, VeriAir Flex, VeriAir, Multi-teq, and ReadyGo are a registered trademarks of Nextteq International LLC. All other brand names and trademarks mentioned in this document are the properties of their respective holders. All features, specifications, and prices are subject to change without notice.

Legal Notice & Privacy Policy | Content Copyright ©2023