Other gas sampling pumps distributed by Nextteq®

Nextteq® International LLC is also distributes the Gastec-brand gas sampling pump. Nextteq® continues to supply custom inventory management and technical support for any Nextteq® Distributor who carries this product.

Configurations Available

Video Instructions

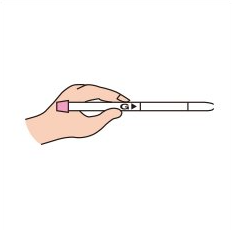

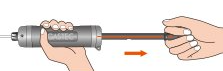

Operating Procedures

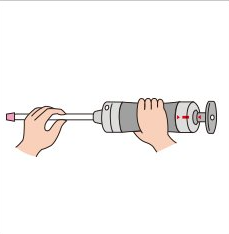

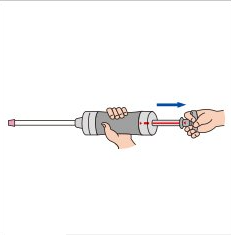

Airtightness Test

If the sampling pump is not airtight, measurements will not yield correct results. Before starting to measure, be sure to verify that the sampling pump is really airtight.